Refractories Market (Form Type - Bricks, Monolithic, and Others; Product Type - Clay Refractory, and Non-clay Refractory; Fusion Temperature - Less than 1580°C, 1580°C to 1780°C, 1780°C to 2000°C, and More than 2000°C; Refractory Minerals - Silicon, Aluminium, Magnesium, Calcium, and Others; Alkalinity - Acid, Basic, and Neutral; Manufacturing Method - Dry Pressing Process, Fused Cast Process, Hand Moulding Process, and Others; End User - Iron and Steel Industry, Petrochemicals, Automotive, Aerospace, and Others): Global Industry Analysis, Trends, Size, Share and Forecasts to 2030

A recent report published by Infinium Global Research on refractories market provides in-depth analysis of segments and sub-segments in the global as well as regional refractories market. The study also highlights the impact of drivers, restraints, and macro indicators on the global and regional refractories market over the short term as well as long term. The report is a comprehensive presentation of trends, forecast and dollar values of global refractories market.

Market Insight:

The refractories hold a crucial role within various industries that operate under high-temperature conditions. These specialized materials, known as refractories, are meticulously designed to endure extreme heat, chemical corrosion, and mechanical strain. Their indispensability is evident across sectors such as steel production, cement manufacturing, glassmaking, and petrochemical refining. In these domains, refractories are vital for lining furnaces, kilns, reactors, and other apparatuses where temperatures routinely surpass the tolerance of conventional materials. The importance of the refractories stems from their capacity to uphold the fundamental operations of these industries by ensuring the longevity and effectiveness of their equipment. As industrial procedures increasingly demand elevated temperatures, heightened resistance to degradation, and improved energy efficiency, the refractories market finds itself on the cusp of growth and innovation. Ongoing advancements in material science and manufacturing methods continuously expand the potential applications and enhance the performance of refractory materials. Consequently, these materials stand as a pivotal cornerstone in facilitating the seamless functionality of high-temperature industries on a global scale.

The burgeoning demand from different industries such as steel, cement, and glass manufacturing is driving the growth of the market. These industries heavily rely on refractory materials to withstand high temperatures, which further propels the market forward. Additionally, the surge in infrastructure projects, especially in developing economies, has further augmented the demand for refractories. Moreover, a notable limitation arises from the industry's significant dependence on the steel and cement sectors, rendering it vulnerable to variations in these domains. Economic contractions or alterations in the demand for steel and cement possess the capacity to directly impact the refractories market, given that these sectors serve as major consumers of refractory goods. However, environmental concerns and regulations related to the use of refractory materials are limiting market growth. However, opportunities lie in technological advancements, such as the development of advanced refractory materials that offer superior performance and longer lifespans. The transition to cleaner energy sources, such as electric arc furnaces in steel production, presents a new market avenue for refractory materials.

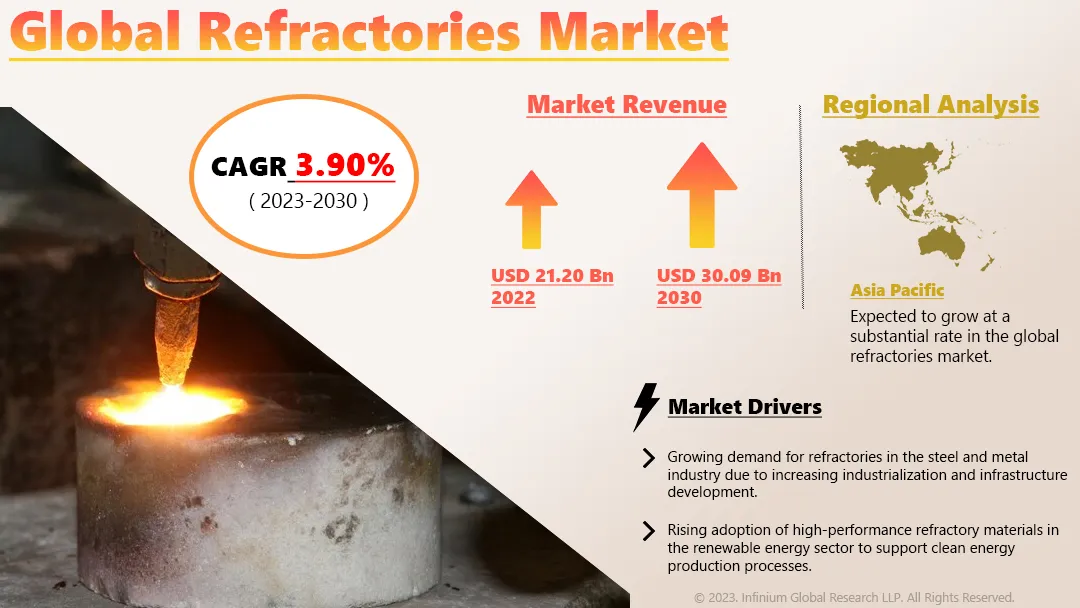

The Asia-Pacific region is expected to grow at a substantial rate in the global refractories market. This commanding position can be attributed to a confluence of factors that have propelled the region to the forefront of this industry. It has witnessed unprecedented industrialization and infrastructure development, leading to a substantial demand for refractories in sectors such as steel, cement, and glass manufacturing. Moreover, the abundant availability of raw materials like high-quality clay, bauxite, and silica in many Asian countries has enabled the cost-effective production of refractory materials, giving local manufacturers a competitive edge in both domestic and international markets. Moreover, North America stands out as one of the fastest-growing regions, signifying a notable transformation in the overall industries. The manufacturing sector in North America has undergone a notable resurgence, primarily propelled by technological advancements, greater automation, and a strong emphasis on energy-efficient processes. This revival has had a substantial impact on the demand for refractories, especially in sectors such as steel, aluminum, cement, and chemicals, where these materials play a vital role in high-temperature applications. Consequently, this upswing has contributed significantly to the expansion of the refractories market in the region.

Report Scope of the Refractories Market:

| Report Coverage | Details |

|---|---|

| Market Size in 2022 | USD 21.20 Billion |

| Market Size by 2030 | USD 30.09 Billion |

| Growth Rate from 2023 to 2030 | CAGR of 3.90% |

| Largest Market | Asia Pacific |

| No. of Pages | 100 |

| Market Drivers |

|

| Market Segmentation | By Form Type, By Product Type, By Fusion Temperature, By Refractory Minerals, By Alkalinity, By Manufacturing Method, and By End User |

| Regional Scope | North America, Europe, Asia Pacific, and RoW |

Segment wise revenue contribution in the global refractories market

The report on global refractories market provides a detailed analysis of segments in the market based on Form Type, Product Type, Fusion Temperature, Refractory Minerals, Alkalinity, Manufacturing Method, and End User.

Segmentation Based on Form Type

· Bricks

· Monolithic

· Others

Segmentation Based on Product Type

· Clay Refractory

· Non-clay Refractory

Segmentation Based on Fusion Temperature

· Less than 1580°C

· 1580°C to 1780°C

· 1780°C to 2000°C

· More than 2000°C

Segmentation Based on Refractory Minerals

· Silicon

· Aluminium

· Magnesium

· Calcium

· Others

Segmentation Based on Alkalinity

· Acid

· Basic

· Neutral

Segmentation Based on Manufacturing Method

· Dry Pressing Process

· Fused Cast Process

· Hand Moulding Process

· Others

Segmentation Based on End User

· Iron and Steel Industry

· Petrochemicals

· Automotive

· Aerospace

· Others

Company Profiled:

· Imerys S.A.

· RHI Magnesita

· POSCO FUTURE M

· Krosaki Harima Corporation

· SHINAGAWA REFRACTORIES CO., LTD.

· Refratechnik

· Plibrico Company, LLC

· INTOCAST AG

· Saint-Gobain

· Other Companies

Report Highlights:

The report provides deep insights into demand forecasts, market trends, and micro and macro indicators. In addition, this report provides insights into the factors that are driving and restraining the growth in this market. Moreover, The IGR-Growth Matrix analysis given in the report brings an insight into the investment areas that existing or new market players can consider. The report provides insights into the market using analytical tools such as Porter's five forces analysis and DRO analysis of the refractories market. Moreover, the study highlights current market trends and provides forecasts from 2023-2030. We also have highlighted future trends in the market that will affect the demand during the forecast period. Moreover, the competitive analysis given in each regional market brings an insight into the market share of the leading players.