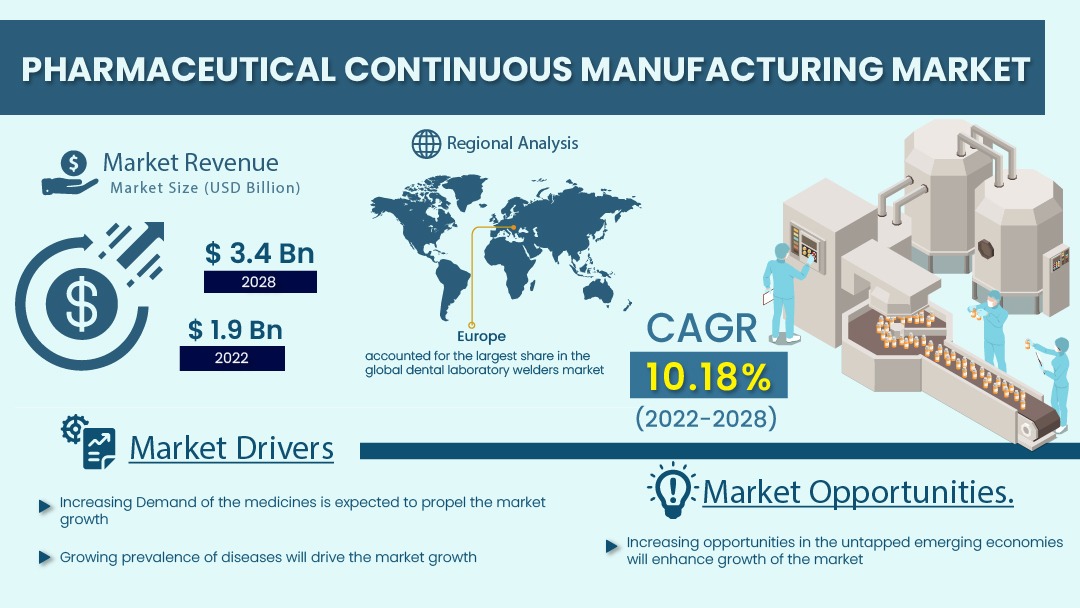

Pharmaceutical Continuous Manufacturing Market (Product - Integrated Continuous Systems, and Semi Continuous Systems; Application - Final Drug Product Manufacturing, and API Manufacturing; End-user - Pharmaceutical Companies, and Contract Manufacturing Organization): Global Industry Analysis, Trends, Size, Share and Forecasts to 2028

A recent report published by

Infinium Global Research on the pharmaceutical continuous manufacturing market

provides an in-depth analysis of segments and sub-segments in the global as well

as the regional pharmaceutical continuous manufacturing market. The study also

highlights the impact of drivers, restraints, and macro indicators on the

global and regional pharmaceutical continuous manufacturing market over the

short term as well as long term. The report is a comprehensive presentation of

trends, forecasts, and dollar values of the global pharmaceutical continuous

manufacturing market. According to the report, the global pharmaceutical

continuous manufacturing market is projected to grow at a CAGR of 10.18% over the

forecast period of 2022-2028.

Market Insight

The global pharmaceutical

continuous manufacturing market was valued at about USD 1.9 Billion in 2022 and

is expected to reach over USD 3.4 Billion in 2028, with a CAGR of 10.18% during

the forecast period. A method used to manufacture or process raw material

without interruption is called continuous manufacturing or flow production.

Pharmaceutical continuous manufacturing technology reduces manual intervention

due to controlled units that provide a high level of automation. In the

pharmaceutical sector, the shift from the traditional batch manufacturing

method to the advanced continuous manufacturing technology is gaining momentum.

Furthermore, the growth of the market is attributed to the factors such as

increasing initiatives by regulatory authorities for the utilization of

continuous manufacturing technology. Moreover, the rising application of PCM

systems is expected to enhance the growth of the market during the forecast

period.

Productive capacity is the maximum

possible output of an economy. According to the United Nations Conference on

Trade and Development (UNCTAD), no agreed-upon definition of maximum output

exists. Hence utilization of production capacity in continuous manufacturing is

driving the growth of the market significantly. This manufacturing technology

provides a better way of manufacturing drug products that save time, improve

quality, create more flexibility in production quantities, and reduce required

production and the material that is to be developed this may turn into an

additional positive factor driving the demand growth. Moreover, FDA has

developed a program on the advancement of emerging technology applications to

modernize the pharmaceutical manufacturing base and frequent discussions with

the agency before the implementation of manufacturing technology. However, the

high implementation cost of automated units for continuous manufacturing is

likely to restrain the growth of the market. The Merger and acquisition and

joint venture among the leading player will bring more opportunities to this

market.

The outbreak of COVID-19 had

positive impacts on the pharmaceutical continuous manufacturing market during

the forecast period. The increasing utilization of medicine due to the

increased spread of the virus during the pandemic enhanced the production of

the pharmaceutical sector. The pharmaceutical sector was an essential element

during the covid-19 pandemic. The spread of the virus was increasing very

rapidly it increasing the demand for the medicines which propelled the growth

of the market during the forecast period. Furthermore, increasing healthcare

systems to treat chronic disease patients increased the utilization of the

technology during the covid-19 pandemic within the forecast period.

Based on the region, the worldwide

pharmaceutical continuous manufacturing market is segmented into the Asia

Pacific, North America, Europe, and also the Middle East & Africa. Europe

is expected to be the largest market for pharmaceutical continuous

manufacturing followed by Asia-Pacific. The demand for advanced technology is

high and the presence of many contract manufacturing organizations has boosted

the market in the region. The U.K. and Germany are the leading

revenue-generating countries in this region. Furthermore, the Asia Pacific is

expected to dominate the growth of the market during the forecast period. The

growth in the Asia Pacific is mainly driven by China and India, due to the

presence of a number of contract manufacturing companies.

Segment Covered

The report on global pharmaceutical

continuous manufacturing market covers segments such as product, application,

and end-user. On the basis of product, the sub-markets include integrated

continuous systems, and semi continuous systems. On the basis of application,

the sub-markets include final drug product manufacturing and API

manufacturing. On the basis of end-user, the sub-markets include pharmaceutical

companies, and contract manufacturing organization.

Companies Profiled:

The report provides profiles of

the companies in the market such as Johnson & Johnson’s, GEA, Korsch AG,

Siemens AG, Corning Life Sciences, Continuous Pharmaceutical, Scott Equipment

Company, S K Biotek Ltd, Chemtrix, and Thermo Fisher Scientific, Inc.

Report Highlights:

The report provides deep insights

into the demand forecasts, market trends, and micro and macro indicators. In

addition, this report provides insights into the factors that are driving and

restraining the growth in this market. Moreover, The IGR-Growth Matrix analysis

given in the report brings an insight into the investment areas that existing

or new market players can consider. The report provides insights into the

market using analytical tools such as Porter's five forces analysis and DRO

analysis of the pharmaceutical continuous manufacturing market. Moreover, the study

highlights current market trends and provides forecasts from 2022-2028. We also

have highlighted future trends in the market that will affect the demand during

the forecast period. Moreover, the competitive analysis given in each regional

market brings an insight into the market share of the leading players.