Coordinate Measuring Machines (CMM) Market (Type - Stationary, and Portable; End User - Automotive, Aerospace & Defense, Energy & Power, Electronics, and Others): Global Industry Analysis, Trends, Size, Share and Forecasts to 2027

A recent report published by

Infinium Global Research on coordinate measuring machines (CMM) market provides an in-depth analysis of segments and sub-segments in the global as well as

regional coordinate measuring machines (CMM) market. The study also highlights

the impact of drivers, restraints, and macro indicators on the global and

regional coordinate measuring machines (CMM) market over the short term as well

as long term. The report is a comprehensive presentation of trends, forecast

and dollar values of global coordinate measuring machines (CMM) market.

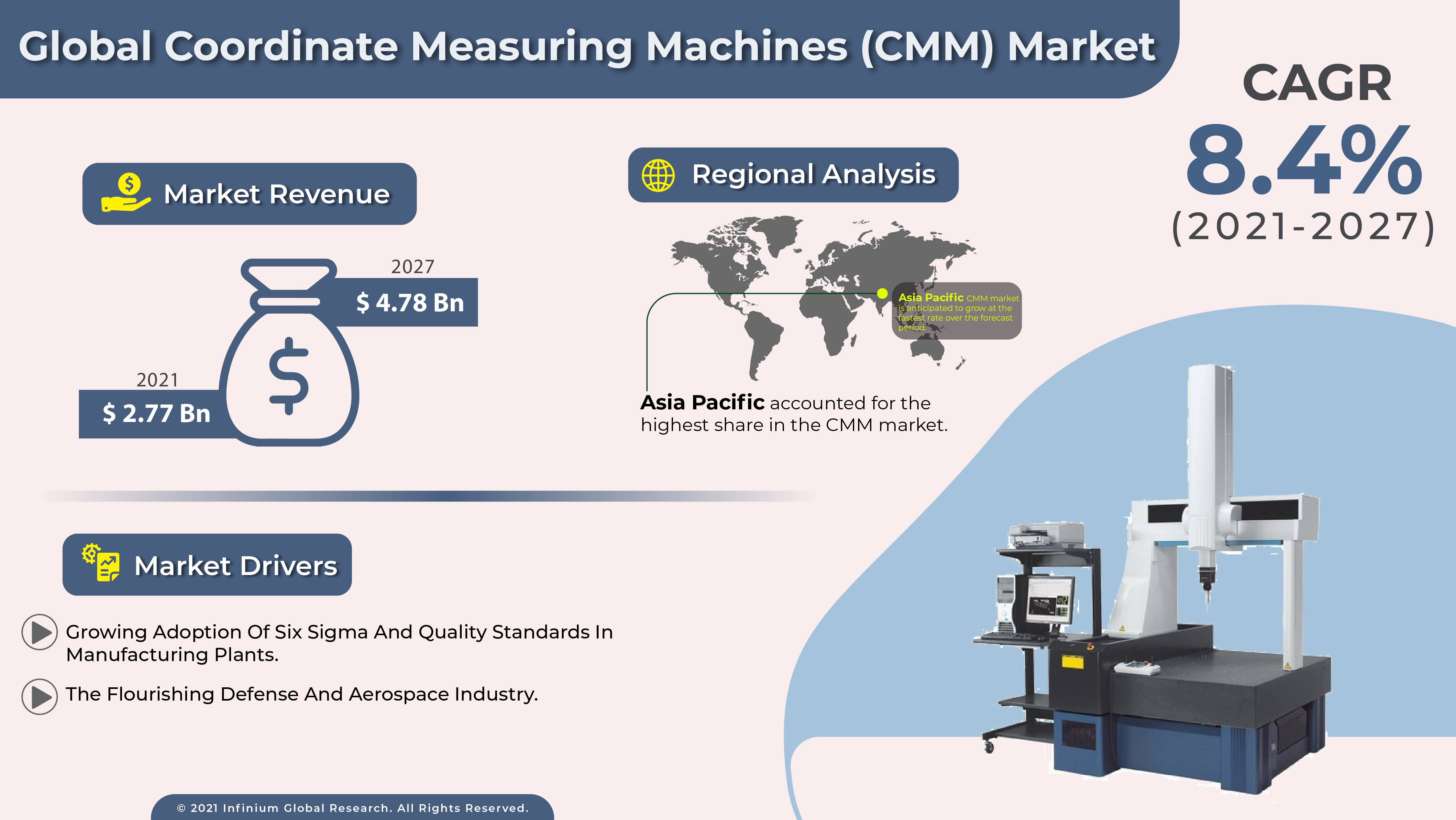

According to the report, the global coordinate measuring machines (CMM) market

is projected to grow at a CAGR of 8.4% over the forecast period of 2021-2027,

growing from nearly USD 2.77 billion in 2020 to about USD 4.78 billion in 2027.

Market Insight

Coordinate measuring machines (CMM)

are used to measure the geometrical dimensions of objects by sensing discrete

points on the surface of the object by a probe. The CMM comes with different

types of probes, including mechanical, optical, laser, and white light. The

probe is controlled either manually by an operator or a computer-controlled

arm. CMMs are generally made of four major components including computer

control system, machine, software, and probe contact or probe non-contact.

These measuring machines have precision measuring capabilities, giving

high-resolution measurements. Due to their high accuracy, several manufacturing

companies use CMMs to inspect their products. Companies from industries such as

automotive, aerospace, energy & power, electronics, and, others widely use CMM

for product inspection. Furthermore, the market players are developing

innovative CMM prototypes to gain a tactical advantage over the competition.

The spread of

COVID-19 negatively affected the CMM market over the short term. Government in

several countries across the world imposed restrictions to control the

pandemic. Many local and national governments implemented lockdowns, compelling

industries to reduce or even stop the business operations. This, in turn,

reduced the demand for industrial equipment such as CMMs, which are used in

manufacturing plants. Moreover, the lockdown restrictions by the governments

disrupted the supply chains across the world. Ports and warehouses in many

countries were closed during the pandemic, which in turn, affected the

transport and supply of raw materials and finished goods. Thus, countries

dependent on the import of machinery, and equipment registered shortages over

the period of the pandemic. This, in turn, hampered the growth of the CMM

market during the pandemic. However, as the pandemic crisis got under control,

the markets opened up and the sale of CMM began to come back to the

pre-pandemic state.

The growing adoption of six sigma

and quality standards in manufacturing plants is mainly driving technological

advancements. Manufacturing plants across several industries are implementing

modern product development processes to improve operational efficiencies. This,

in turn, boosts the growth of the CMM market. Moreover, the flourishing defense

and aerospace industry is expected to augment the demand for CMM. The

components used in the defense and aerospace industry are required to be of

highly accurate dimensions. Thus, CMMs play an important role in inspecting the

components used in the defense and aerospace industry. However, the

availability of alternative measuring machines is likely to hinder market

growth over a short period. Nevertheless, the growing trend of industrial

automation is anticipated to boost the market in the future. Modern

technologies such as cloud computing, and IIoT offer growth opportunities to

the market players.

The Asia Pacific accounted for the

highest share in the CMM market among other regions in the world. Moreover, the

Asia Pacific CMM market is anticipated to grow at the fastest rate over the

forecast period as compared to other regional markets. The growing number of

manufacturing units built in the region is majorly driving the growth of the

market. furthermore, the increasing investment for infrastructure development

by the government and private players is further supporting the growth of the

Asia Pacific CMM market. On the other hand, North America accounted for the

second-largest share in the global CMM market. The presence of major

manufacturing plants in the region is augmenting the growth of the North

American CMM market.

Segment Covered

The report on global coordinate

measuring machines (CMM) market covers segments such as type, and end user. On

the basis of type, the sub-markets include stationary, and portable. On the

basis of end user, the sub-markets include automotive, aerospace & defense,

energy & power, electronics, and others.

Companies Profiled:

The report provides profiles of

the companies in the market such as CMM Solutions (UK) Ltd., Carl Zeiss AG

(Zeiss Group), Ametek Inc. (Creaform), Faro Technologies, Inc., Nikon

Corporation, Keyence Corporation, Wenzel Group GmbH & Co. KG, Eley

Metrology Ltd., Hexagon AB, and Sipcon Instrument Industries.

Report Highlights:

The report provides deep insights

into the demand forecasts, market trends, and micro and macro indicators. In

addition, this report provides insights into the factors that are driving and

restraining the growth in this market. Moreover, The IGR-Growth Matrix analysis

given in the report brings an insight into the investment areas that existing

or new market players can consider. The report provides insights into the

market using analytical tools such as Porter's five forces analysis and DRO

analysis of coordinate measuring machines (CMM) market. Moreover, the study

highlights current market trends and provides forecast from 2021-2027. We also

have highlighted future trends in the market that will affect the demand during

the forecast period. Moreover, the competitive analysis given in each regional

market brings an insight into the market share of the leading players.